Because of inert gas atomization and rapid solidification of droplet deposition ,the spray formed die steel has low oxygen content , overall high density and fine microstrcture.

HEYE Special Steel Co., Ltd is the first to achieve industrialization in domestic.Spray forming technology is atomizing the molten metal or alloy in an inert atmosphere into small solid, semi-solid or liquid melt jet, then spraying directly onto the cold substrate surface, droplet deposition on the surface adhesion, accumulation, spreading, fusion, consolidation and the formation of deposited blank. Because of inert gas atomization and droplet deposition rapid solidification, the billets is with low oxygen content, the high density, homogeneous and fine microstructure, and the carbide distribution of the large cross section steel bar has been improved greatly.

Spray steel product advantages : 1) cost-effective, performance meets or exceeds the powder steel , the price is much lower than steel powder ; 2) suitable for multi- variety, small batch-production, high-quality, fast delivery.3) green .

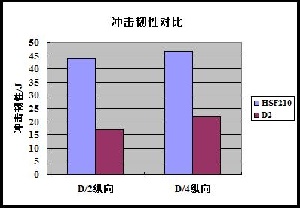

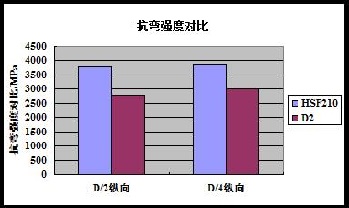

Figure 1-2 show the comparison of mechanical properties between spray formed steel and and electroslag remelted steel.

Fig.1 Comparison of impact toughness

Fig.2 Comparison of bending strengh

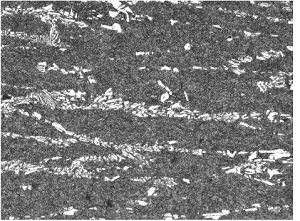

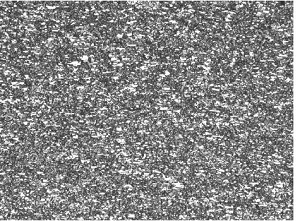

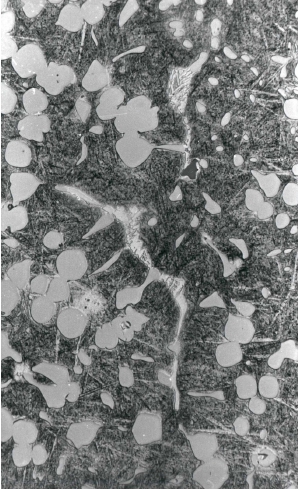

Figure 3-4 show the the contrast of microstructure between HSF210 and D2.

Fig.3 Microstructure of electroslag remelted steel after hot forging, 100x

Fig.4 Microstructure of spray formed steel after hot forging, 100x

Figure 5 is Compare 12V steel structure: the left from the conventional cast sample of 20 mm, right from the sample injection, Picric acid corrosion, 300x.

Fig.5 Compare 12V steel structure

| Type | Specification (mm) | Surface condition |

|---|---|---|

| Forged Round Bar | ∮80-400 | Wheeled/Turned |

| Hot-rolled Round Bar | ∮8-25 | Black |

| ∮21-95 | Turned/Peeled | |

| Peeled Bar | ∮15-150 | Turned |

| Hot-rolled Square Bar | 7.2×7.2~27×27 | Black |

| Hot-rolled Flat Bar | (3.5-40)×(16-100) | Black/Shot Blast |

| Hot-rolled Wire Rod | ∮5.5-17 | Black |

| Cold-drawn Steel Wire | ∮2.0-16.5 | Black |

| Ground Wire | ∮5.0-14.5 | Ground |

| Steel Plate | (2.0-15.0)×(500-700) | Black |

| Hot-rolled Strip | (36-65)×(1.5-3.0) | Black |

| Cold-rolled Strip | (25-55)×(0.65-1.80) | Polished |

| Forged Product | Circular ∮(50-350)×(10-300) | Black/Machined |

| Rectangle (20-200)×(5-80) |