Complete sets of equipment required for the supply unit,And responsible for the installation and commissioning of the installation and on-site technical service work,Ensure that the mill meets the design requirements.In order to get more high-grade produc

Complete sets of equipment required for the supply unit,And responsible for the installation and commissioning of the installation and on-site technical service work,Ensure that the mill meets the design requirements.In order to get more high-grade products,After annealing, the strip should be smooth,Temper rolling is a mild cold rolling of the strip

Improve the mechanical properties of the strip without changing the thickness of the plate.The purpose is to eliminate the yield platform, to prevent the continuous processing of uneven deformation、To prevent the continuous processing of uneven deformation,Increase tensile strength,Expand the range of plastic deformation,According to the requirements of the strip surface hardness and roughness.

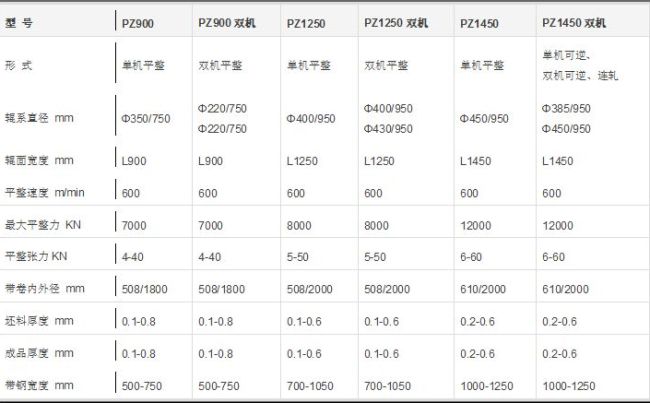

AT&M Environmental Engineering Technology Division after many years of research,Combined with the performance requirements of different products,Develop a variety of products to adapt to the formation of different products,There is a single flat, flat pull straightening unit, two machine flat, two units of cold rolling mill and other products.So far,it has successfully promoted the formation of more than 20 sets of various types of units, has been the majority of users.

Main technological parameters of PZ series flat set,Main technological parameters of MSB series six roller reversing cold mill

三、Unit composition

1200mm machine unit is composed of mechanical equipment, hydraulic system, electric drive system, PLC system, extension rate control system, lubrication system and instrument system.

四、Unit installed level

1.1200mm double machine flat rolling unit adopts domestic advanced two times of cold rolling and smooth technology to ensure product quality not less than GB/T2520-2008 in the corresponding product requirements, at the same time to ensure the production efficiency of the unit.

2 before and after the preparation of S roll, to meet the different requirements of the tension in the course of the drive, the drive mode for the work of the roller drive, double roller drive, smooth current work roll drive.

3 host, uncoiler, coiler and S tension roller adopts DC motor drive.

4. In order to cope with the elongation control system. This unit is equipped with imported high precision encoder, Sony position sensor, the imported tension, rolling pressure sensor to measure advanced testing instruments provide accurate input signal, with the hydraulic servo system, can achieve high precision quick response and to achieve constant extension rate control.

5 the shape of the product is controlled by the roll deviation (tilt control), the working roll forward / negative bending roll and other control means.

6. The uncoiler with CPC automatic function. Uncoiling of the CPC on the EMG products in Germany, in order to accurately control the position of the center of the strip remained at the position of the rolling center line.

7 and the quick roll change. In order to improve the utilization rate of temper mill and reduce the auxiliary time, set up the work roll and backup roll roll change device. Work roll change and car with sliding car quick roll change device, can realize the rapid replacement of work roll.

8 the output of the flat machine is equipped with a high-precision thickness measuring instrument, which is used to monitor the thickness of the product.

9. Leveling machine speed closed-loop control, uncoiling, coiling machine and a machine frame speed / tension closed-loop control, digital display. Interstand tension closed loop by high precision direct tension, and the packet is fixed angle structure, can accurately control unit frame tension.

10. Flat with rolling line height automatic adjustment system. After each change and, for the realization of automatically and accurately regulate the function of rolling line, in the upper part of the housing window set a set of automatic rolling line elevation adjustment device. When the roll change and input new roll diameter, the computer program can be according to the new and to calculate the diameter of the rolling line position, through the built-in position sensor accurate automatic rolling line elevation.

11 unit production process interlock and fault alarm using PLC programmable control, realize the automation of production process.

12 unit with the process parameters of the pre setting, process parameters and the key parameters of the device detection, display, alarm function.

13 flat machine with a man-machine interface, complete the dynamic picture display.

14 units have quasi stop working roller coiling machine, jaw position to stop.

15 the unit has the production report statistics function.